Data

Disk with Pins

When the vertical sand grinder SLG-64G was used with flat discs in pulverizing calcium carbonate, the slurry and medium (glass beads) formed solid balls in between the discs. The idea for developing our disc with pin occurred when we attached a vertical pin on flat discs in order to prevent the formation of balls. The rotational flow of the medium becomes faster with discs with pins than flat discs.In addition to that, the circulatory flow moving up and down becomes substantial.

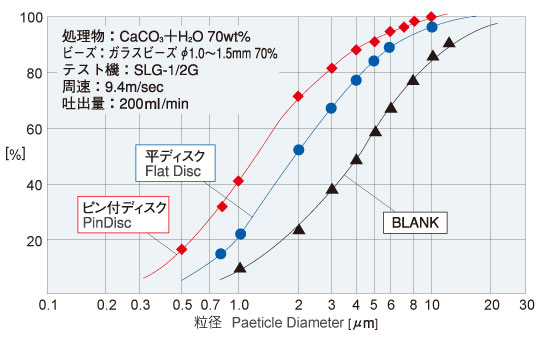

Comparison of Pulverization Capability between Disc with Pins and Flat Disc

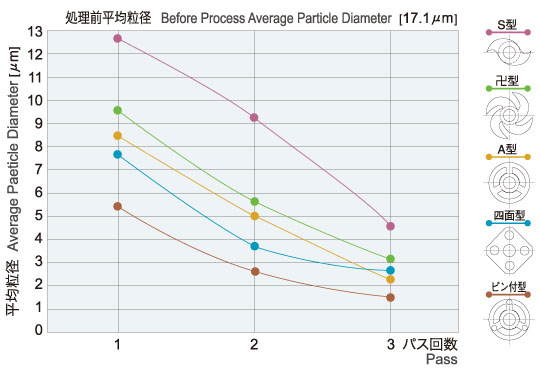

Comparison of Pulverization Capability among Differently Shaped Discs

Test Setting

- Bead Mill:SLG-1/2

- Rotational Disk Speed : 9m/s

- Medium: Glass Bead φ1.0-1.5 mm

- Processed Sample: Calcium Carbonate

- Passage: 3

Rotational Speed of Discs with Pins and Its Pulverization Effect

With regards to wet medium agitation mills, generally, the pulverization speed increases with the increase of the disc speed. The effect becomes substantially smaller at below 10m/sec. In order to break the barrier, we have worked many years on the improvement of discs and as a result of continuous experiments have arrived at the following.

- The factor that dominates pulverization capability is the rotational speed of the medium.

- With flat discs, the speed of the medium gets higher further away from the center,and keeps relatively constant around the center between the discs.

- With discs with pins, thanks to the pins, the circulatory flow of the pins puts pressure on the circulatory flow on the flat side of the other disc, making a larger change of the speed of the medium.

- The rotational flow near the pins has a rapid change in speed on both sides of the pins.

- Due to this ,discs with pins are thought to make difference in rotational speeds in areas near the pins and in the central part between the discs.

- Therefore, discs with pins have a wider range of pulverization due to the existence of the pins.

- Even if the speed of the disc and the average speed of the medium are slow, the ratio at which the medium captures the particles to be pulverized becomes greater if the change in speed is greater. This is why the discs with pins were developed. These discs with pins have been tested by many users in various fields, and the disc speed during those tests has been around 6-12m/sec.

Advantages of Lower Rotational Speed

The standard rotational speed of a disc with pin is 6-12m/sec. When the speed of the disc is made slower, not only is the loss of the medium by wear decreased, but the wear of mechanical parts (disc, vessel, etc.) is also decreased, thus preventing pollution of the product. Also, sudden heat is prevented having less harm on the processed substance. With less worsening of the dispersing agent by the heat, the rise in viscosity can also be prevented.