Neo-Alphamill

NEO-Alphamill NAM

Neo-AlphaMill is a bead mill dedicated to nano-dispersion for production.

This machine produces high quality nano particles by a highly dense layer of beads and highly efficient dispersion layers with Delta-V Disks. These layers processes "all residual coarse particles" that cause quality deterioration.

"Goodbye, coarse particles."

φ0.03~0.3mm

Key Benefits

No.1

High-quality

nano-dispersion

~Drastic reduction of coarse particles~

The two areas ensure a depletion of coarse particles.

1/20 the number of coarse particles compared to conventional mills※

No.2

Sharp

particle size distribution

Adopting a long body reduces short passes.

Processing with 30% UP efficiency than conventional mill ※

No.3

long life

・The stirring materials have no protrusions.

・ Since there is only one rotating shaft, there is only one mechanical seal

Processing results for 4 years without replacement of parts※

No.4

Good scale-up

Even if NAM scales up, this machine can process production volumes equal to several times the mill capacity ratio.

26 times more production from NAM-1 to NAM-20※

※All values will fluctuate depending on the processing conditions.

Neo-Alpha Mill desktop type "S-NAM type" debuts!

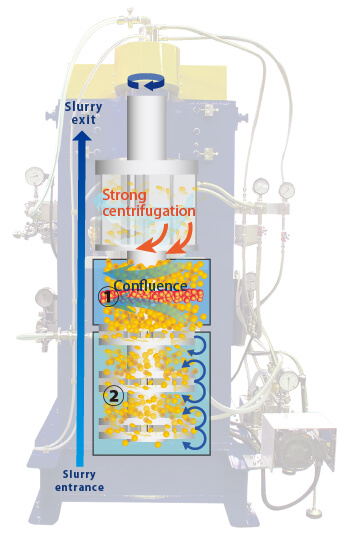

Two areas that enable high quality nano dispersion

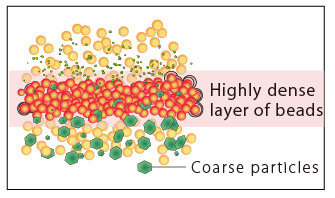

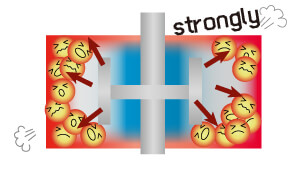

①Highly dense layer of beads

Area where beads are densely gathered by two centrifugal forces

- In the highly dense layer of beads, the flow of beads is slow and excessive energy is not applied, so that it is difficult to over-dispersion.

- The slurry always passes through the highly dense layer. It catches coarse particles in this area, preventing short passes.

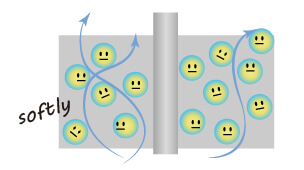

② High-efficiency dispersed layer

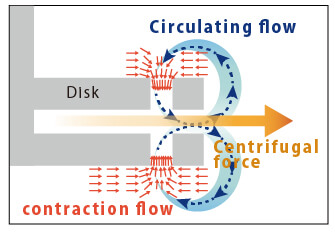

Delt-V disc patented technology

Simple disc with no protrusions.

Special structure that produces centrifugal force, contraction flow, and circulating flow.

- The beads are circulated at high speed to increase the strength and frequency.

- The contraction flow creates a velocity difference, and the shearing force accelerates dispersion.

Highly dense layer space where beads move slowly

The beads move slowly to prevent overdispersion. Because it is densely packed, it can be reliably caught without missing coarse particles.

◎Efficient work

Since the beads are pressed against the narrow space of the vessel or disc, it causes irregular heat generation, chipping, and overdispersion.

△Inefficient work

When the space between the vessel and the disc is widened, the bead density is low and the processing speed is slow. Coarse particles may remain.

△Inefficient work

Structure that reduces wear

・Beads highly dense layer reduces wear because the speed of beads is slow.

・Disc shape without protrusions

Long life and high efficiency processing

Areas where wear is often observed

・Around the disc where the beads are moving at high speed

・Protrusions on/in Discs and vessel

Wear causes reduced efficiency

Processing example

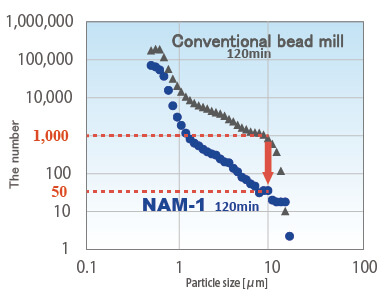

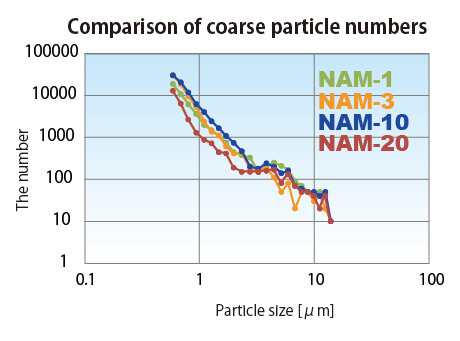

Residual coarse particles that are not detected

by the particle size analyzer are drastically reduced.

| NAM-1 | Conventional bead mill | |

| Vessel capacity | 0.8L | 0.7L |

| Beads | Zro2φ0.1mm | ZrO2φ0.1mm |

| Flow rate | 0.8L/min | |

| Disk speed | 8.5m/s | |

| Slurry | 0wt% CaCo3(With water) | |

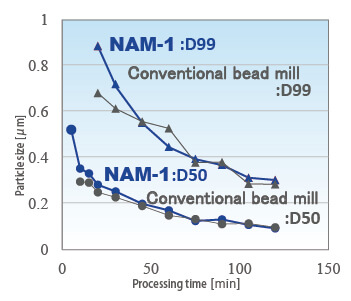

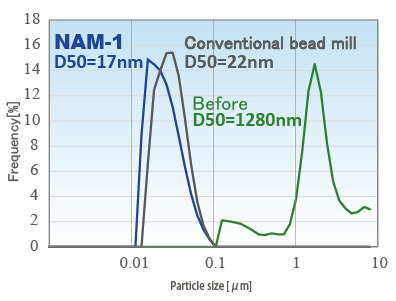

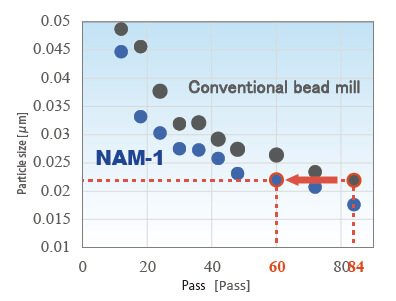

■ Even particle size distributions are same,

the number of coarse particles that particle size analyzer can't detect by Neo-AlphaMill is 1/20 smaller than prior AlphaMill.

Efficiently realizes high-quality nano-dispersion

| NAM-1 | Conventional bead mill | |

| Vessel capacity | 0.8L | 0.7L |

| beads | ZrO2 φ0.03mm | |

| Flow rate | 0.4L/min | |

| Disk speed | 10m/s | |

| Slurry | 10 wt%TiO2 | |

| Primary particle diameter | 15nm | |

■ Sharp particle size distribution and processing efficiency 30% UP

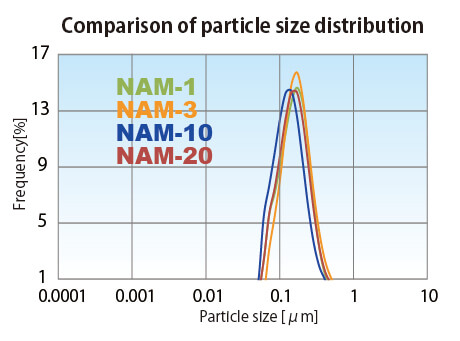

Good scale-up

Neo-Alpha Mill processed 20% Calcium Carbonate on 4 Scales (NAM-1,3,10,20)

| Mill capacity ratio | Production [kg / h] | Comparison of production ratio | |

|---|---|---|---|

| NAM-1 | 1 | 1.6 | ー |

| NAM-3 | 4 | 8 | 4times |

| NAM-10 | 12 | 18 | 11times |

| NAM-20 | 24 | 41 | 25times |

■ Even if the scale is increased, the processing performance does not change, and the production volume can be increased to the same level as the mill capacity.

Use

Ink pigments / dyes, fine ceramics, catalysts, magnetic recording raw materials, etc.

specification

| S-NAM | NAM-1 | NAM-3 | NAM-10 | NAM-20 | |

|---|---|---|---|---|---|

| Practical capacity | 0.165L | 0.81L | 3.1L | 9.5L | 18.5L |

| beads | 0.03~0.3mm | 0.03~0.3mm | 0.03~0.3mm | 0.05~0.3mm | 0.05~0.3mm |

| Motor capacity | 0.75kW | 5.5kW | 11kw | 22kW | 37kW |

| Approximate dimensions | W300×D590 ×H604mm |

W1,100×D1,100 ×H1,800mm |

W1,250×D1,250 ×H1,800mm |

W1,500×D1,400 ×H2,100mm |

W1,800×D1,500 ×H2,500mm |

| Slurry contact material | Ceramics, resin | ||||

※This specification is subject to change without notice due to improvements, etc.

※Explosion-proof specifications are required when using in places where there is a danger of ignition or when using organic solvents.

※The dimensions of the operation panel and relay terminal junction box will be fixed after the specifications are decided.