easynano

EasyNano RMBⅡ

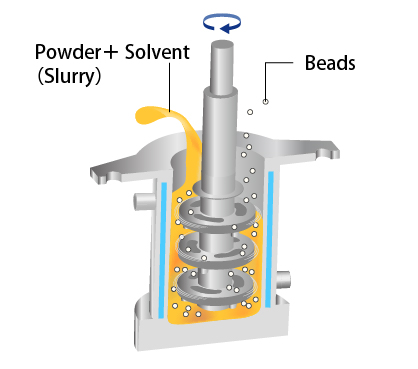

Ease of use No.1 Standard model of small desktop lab machine.Bead milling can be performed simply by adding the slurry, beads and rotating.

Micro beads can be also used.With AC100V power supply, you can easily utilize a bead mill. Since it can process from 30 mL, it is also ideal for processing expensive materials.

"The first bead mill starts here."

100V power supply

φ0.03~2.0mm

Features of Easy Nano

No.1

Small amount processing

Processing of 30 mL to 400 mL is

possible by exchanging the vessel set . Easy to search scale up to a continuous bead mill.

No.2

Vessel set disassembly / replacement 30 seconds. Easy preparation and cleaning work.

Greatly improved processing efficiency by powerful operation with a maximum peripheral speed of 12m/s.

No.3

Space-saving

maintenance-free

Footprint of Tabloid paper x 1 sheet.

Due to its simple structure, daily inspection is not required.

No.4

No restriction

There is no limit to the bead diameter as long as it is φ2.0 mm or less.Easy to manage (processing time = detention time operation)

No.5

low cost

Initial cost is the lowest in the class.

Minimum price 1.5 million yen ~

No.6

Abundant options

We have bead separation containers and continuous circulation operation units. Explosion protection is also available.

What you can do with Easy Nano

① Increase processing efficiency

Maximum peripheral speed 12 m/s, maximizes slurry installation by semi-sealed lid.

Enable to select multiple beads and easily study the optimum bead diameter.

Multiple composition such as dispersants and binders can be easily examined.

It is possible to study the operation conditions with focusing actual production since maximum peripheral speed can be up to 12 m/s.

Just add powder, solvent and beads and rotate

Since it is a batch type that does not use a pump, there is no need to worry about solution sending problems. Anyone can easily use it for a wide range of slurry and products.

Small desktop size saves space

Since it is small body, it can be installed in a draft chamber.

30 seconds for disassembly and assembly

Since cleaning does not take much time, it is possible to handle a large number of tests required for setting conditions.

Small amount processing

| Model | 01 | 02 | 04 | 08 |

|---|---|---|---|---|

| Standard pour amount guide | 30mL~ | 60mL~ | 100mL~ | 300mL~ |

Explosion-proof model available

■Motor, operation panel

…Explosion-proof structure

■Control panel

…Air purge specifications, etc.

the photo on the left, the motor has an explosion-proof structure, and the instrument and emergency stop switch have an intrinsically safe explosion-proof structure.

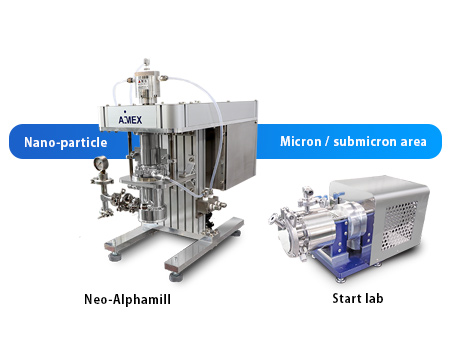

Scale up from a lab machine

- Nano-particle

Neo-Alpha Mill is recommended - Micron / submicron area

start lab is recommended

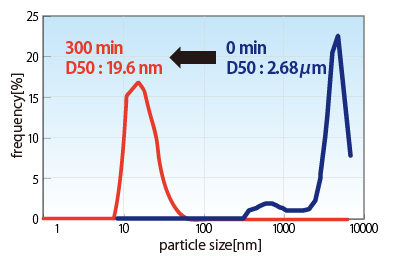

Processing example

| Processed material | alumina |

|---|---|

| Disk peripheral speed | 3.1m/s |

| Beads | φ0.03mm Zirconia |

| Target particle size | D50=20nm |

Application

We can handle secondary battery materials, magnetic recording raw materials, fine ceramics, ink pigments / dyes, papermaking, rubber / latex, cosmetics, pesticides, pharmaceuticals / foods, textile additives, photocatalysts, and any other processed products. When starting a bead mill, please try this model first.

specification

| Model | 01 | 02 | 04 | 08 |

|---|---|---|---|---|

| Nominal capacity | 100mL | 200mL | 400mL | 800mL |

| Standard pour amount guide | 30mL~ | 60mL~ | 100mL~ | 300mL~ |

| Power supply | AC100V | |||

| motor | 0.75kW | |||

| Rotation speed | max 5730 rpm | |||

| Usable bead diameter | φ0.03~2.0mm | |||

| Liquid contact material | Zirconia, silicon nitride, urethane, SUS, glass (vessel only), etc. | |||

| 備考 | Temperature control is possible because it has a cooling jacket. The above vessel can also be used with explosion-proof specifications. Pleas contact us even RMB(old model) vessel cannot be installed. |

|||

※This specification is subject to change without notice due to improvements, etc.

※Explosion-proof specifications are required when using in places where there is a danger of ignition or when using organic solvents.

※The dimensions of the operation panel and relay terminal junction box will be fixed after the specifications are decided.